Chigadzirwa chakanaka hachingogadziriswi chete, asi chinodawo kurapwa kwakasiyana-siyana kwepamusoro kuti uwane corrosion resistance, kupfeka kuramba, aesthetics, uye kuwedzera hupenyu hwebasa.RCT MFG ine makore mazhinji echiitiko muCNC kugadzirisa uye jekiseni molding processing, zvakare inopa akatevedzana masevhisi kubva pakugadzirisa kusvika pakurapwa kwepamusoro kusvika pakusangana.Naizvozvo, kuwedzera kune tekinoroji yekugadzira, ine zvakare ruzivo rwakapfuma mukurapa kwepamusoro.Iwo aripo pamusoro pekurapa maitiro anosanganisira: kupenda, Baking pendi, poda coating, sandblasting, kupfura kuputika, anodizing, gobvu firimu anodizing, micro-arc anodizing, electroplating, electrophoresis, laser engraving, silk screen kudhinda, brushed metal, mirror polishing, dyeing, kusviba, CD pattern, etching, high gloss, etch pattern, Epoxy, nezvimwewo, batsira kugadzira zvigadzirwa zvako padanho repamusoro.

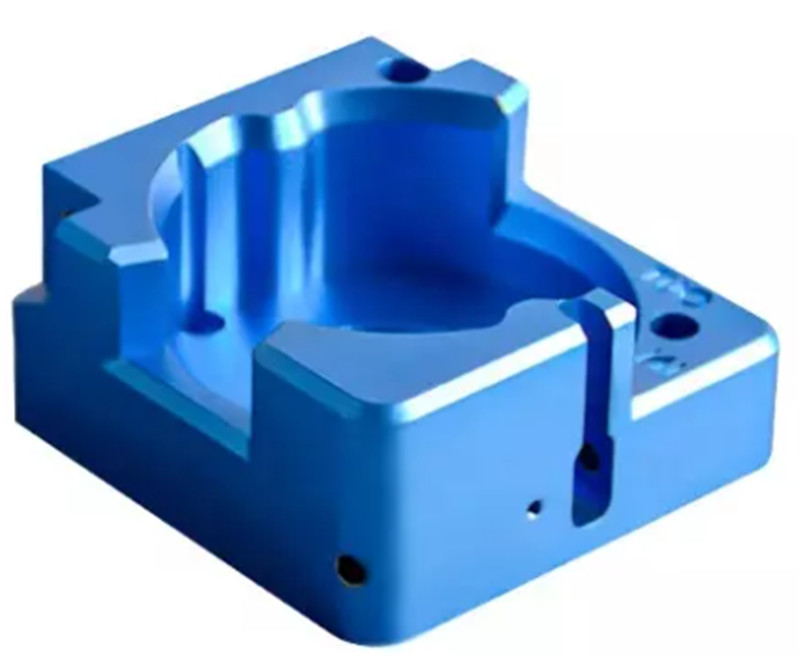

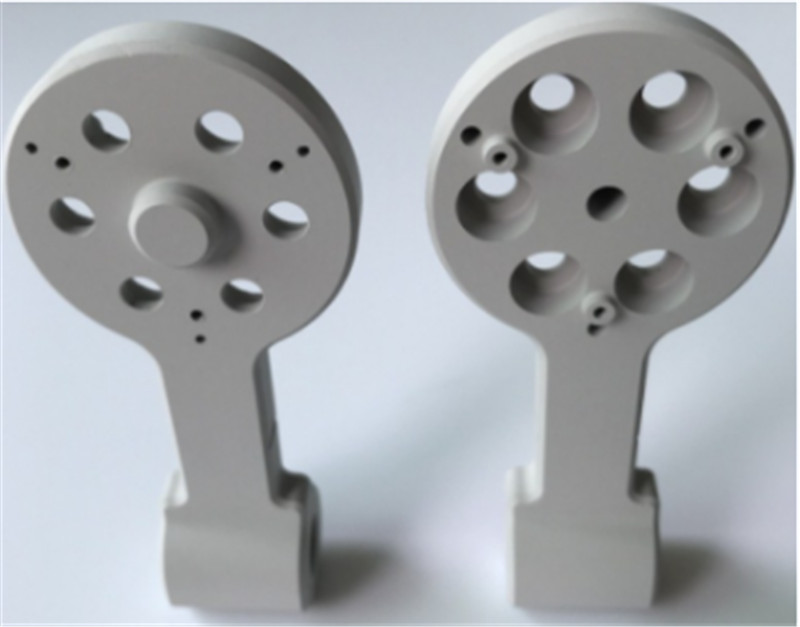

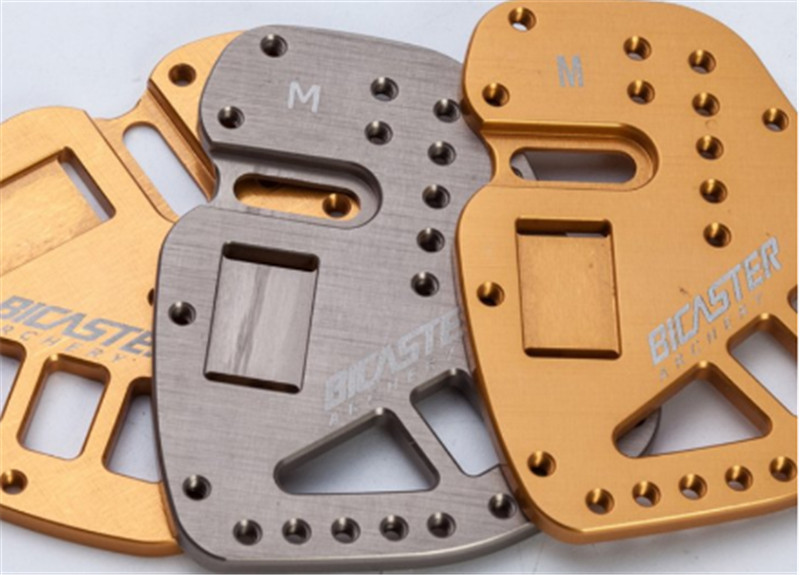

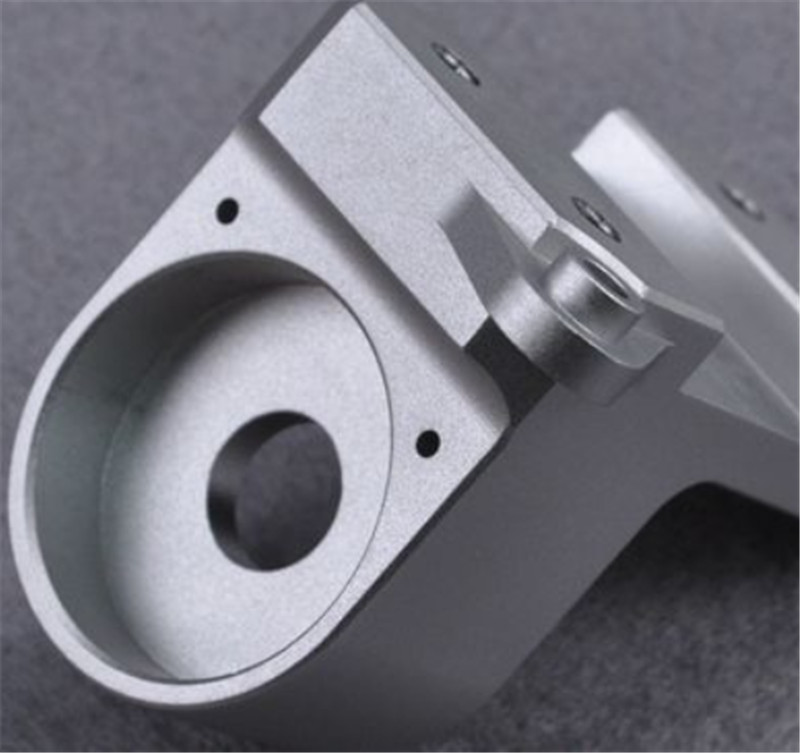

Anodizing

Iyo inonzi electrolytic oxidation process, inoshandura pamusoro pezvinhu kuita firimu rinodzivirira, zvichiita kuti zviome kuisa oxidize uye corrode, kurebesa hupenyu uye kuwana kutaridzika kwemavara akasiyana.Mishonga inowanzoshandiswa inodizing yakakamurwa kuva: common anodizing , brushed metal anodizing, hard anodizing, gobvu firimu anodizing, micro-arc oxidation, etc. Zvinhu zvinogona kuve oxidized ndezvi: aluminium alloy, magnesium alloy, titanium alloy, nezvimwewo.

Electroplating

Iyo yakakosha maitiro e electroplating ndeyekunyudza chikamu mumhinduro yesimbi munyu se cathode, uye ndiro yesimbi seanode, uye kupfuudza ikozvino kuisa iyo yaunoda coating pachikamu.Iyo yakakodzera electroplating mhedzisiro ichaita kuti chigadzirwa chako chiwedzere fashoni yepamusoro uye nacho.Kumusika uri nani, yakajairwa electroplating inosanganisira copper plating, nickel plating, sirivheri plating, goridhe plating, chrome plating, galvanizing, tin plating, vacuum plating, nezvimwe.

Electrophoretic coating

Nekuenderera mberi kwekuvandudzwa kwezvinodiwa zvemaindasitiri, Electrophoretic coating tekinoroji inogona kugadzirisa mavara akasiyana, kuchengetedza simbi inopenya uye kuwedzera kusimba kwekuora kwepamusoro, izvo zvine zvishoma zvinokanganisa kurongeka kwechigadzirwa.Ukobvu hunenge 10-25um, uye dzakakora dziri zvakare Inogona kugadzirwa

Passivation

Passivation, inozivikanwawo se chromate kurapwa, inzira yekunhonga inobvisa pamusoro pegirisi, ngura, uye oxides nekunyudza kana ultrasonic kuchenesa.Kuburikidza nemakemikari anoita yepassivation solution, inogona kudzivirira ngura uye kuwedzera ngura.Muvara wefirimu yepassivation ichachinja nezvinhu zvakasiyana.Passivation haizowedzere kuwanda kwechigadzirwa, uye hapana chikonzero chekunetseka pamusoro pacho chinokanganisa kurongeka kwechigadzirwa.

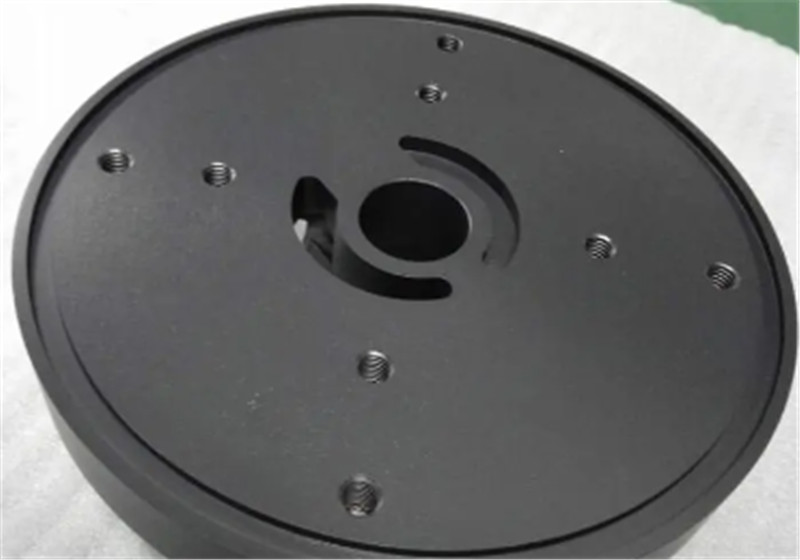

Blackened

Blackening inonziwo bluing.Nheyo yacho ndeyekunyudza chigadzirwa mune yakasimba oxidizing kemikari mhinduro kuumba oxide firimu pane simbi pamusoro kuparadzanisa mhepo uye kuzadzisa chinangwa chekudzivirira ngura.Iyi nzira inoshandiswa kune zvinhu zvesimbi.

QPQ (Quench-Polish-Quench)

Zvinoreva kuisa zvikamu zvesimbi zvine ferrous mumhando mbiri dzekugezesa munyu dzine zvinhu zvakasiyana, uye kupinza zvinhu zvakasiyana-siyana mukati mesimbi kuti iite mubatanidzwa wekupinda mukati, kuti uwane chinangwa chekugadzirisa pamusoro pezvikamu.Iyo ine yakanaka kupfeka kuramba, kuneta kuramba, corrosion resistance uye kudiki deformation.Iyi nzira inoshandiswa kune zvose zvinhu zvesimbi.

(Cherechedza: Zvigadzirwa zvesimbi isina simbi hazvigone kusvibiswa, uye nzvimbo yacho inogona chete kusvibiswa neQPQ)

Laser engraving

Laser engraving, inonziwo laser yekumaka, inzira yekurapa pamusoro uchishandisa optical misimboti kugadzira LOGO kana mapatani pane zvigadzirwa.Iyo laser engraving athari ndeyekusingaperi, iyo yepamusoro mhando yakakwira, uye inokodzera zvigadzirwa zvakagadzirwa neakasiyana simbi uye epurasitiki zvinhu.

Silk screen kudhinda

Silk screen printing inoreva kuti ingi inotamisa pateni kuchigadzirwa kuburikidza nechidzitiro.Ruvara rweinki runogona kugadzirwa maererano nezvinodiwa nevatengi.RCT MFG yakaita 6 mavara pachigadzirwa chimwe chete, kusanganisira nhema, tsvuku, bhuruu, yero uye chena.,girinhi.Kana iwe uchida kuti mhedzisiro yekudhinda sirika skrini iwedzere kusimba, iwe unogona zvakare kuwedzera layer yeUV mushure mekudhinda sirika skrini kuti urebese hupenyu hwayo.Silk screen printing inokodzera akasiyana simbi uye epurasitiki zvinhu, uye inogona zvakare kusanganiswa nepamusoro kurapwa senge oxidation, pendi, poda yekupfapfaidza, electroplating, uye electrophoresis.

Kupukuta

Kupukuta ndiko kuita kuti chigadzirwa chive chakanaka, chinopenya uye kudzivirira pamusoro.Kupenya uye pachena isarudzo yakanaka kwauri.Iko kukwenenzverwa kwezvigadzirwa zve Hardware kwakakamurwa kuita manual polishing, mechanical polishing, uye electrolytic polishing.Electrolytic polishing inogona kushandiswa kutsiva inorema mechanic polishing, kunyanya kune zvikamu zvine maumbirwo akaomarara uye zvikamu zvinonetsa kugadzirisa nekupukuta kwemanyorero uye nemakanika nzira.Electrolytic polishing inowanzoshandiswa simbi, aruminiyamu, mhangura uye zvimwe zvikamu.

Brushed Metal

Brushed simbi inzira yekurapa pamusoro inoumba mitsetse pamusoro peiyo workpiece kuburikidza ne flat-pressed abrasive bhandi uye isina-yakarukwa roller bhurashi kuti iwane yekushongedza mhedzisiro.Brushed surface treatment inogona kuratidza kugadzirwa kwesimbi, uye iri kuramba ichizivikanwa muhupenyu hwanhasi.Inoshandiswa zvakanyanya munharembozha, makomputa, monitors, fenicha, midziyo yemagetsi uye mamwe magomba.

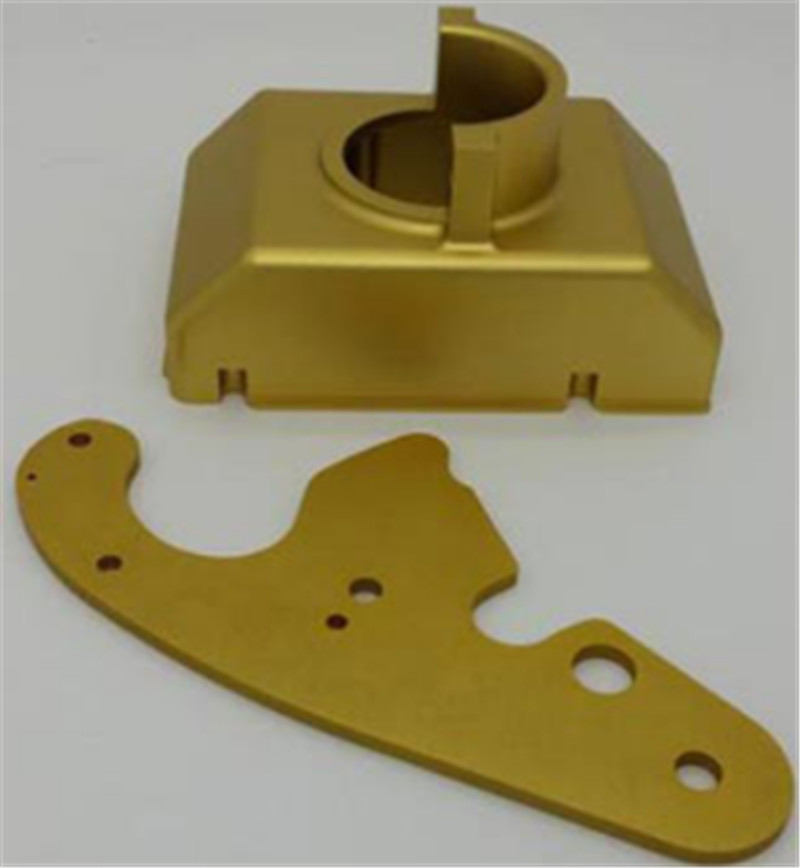

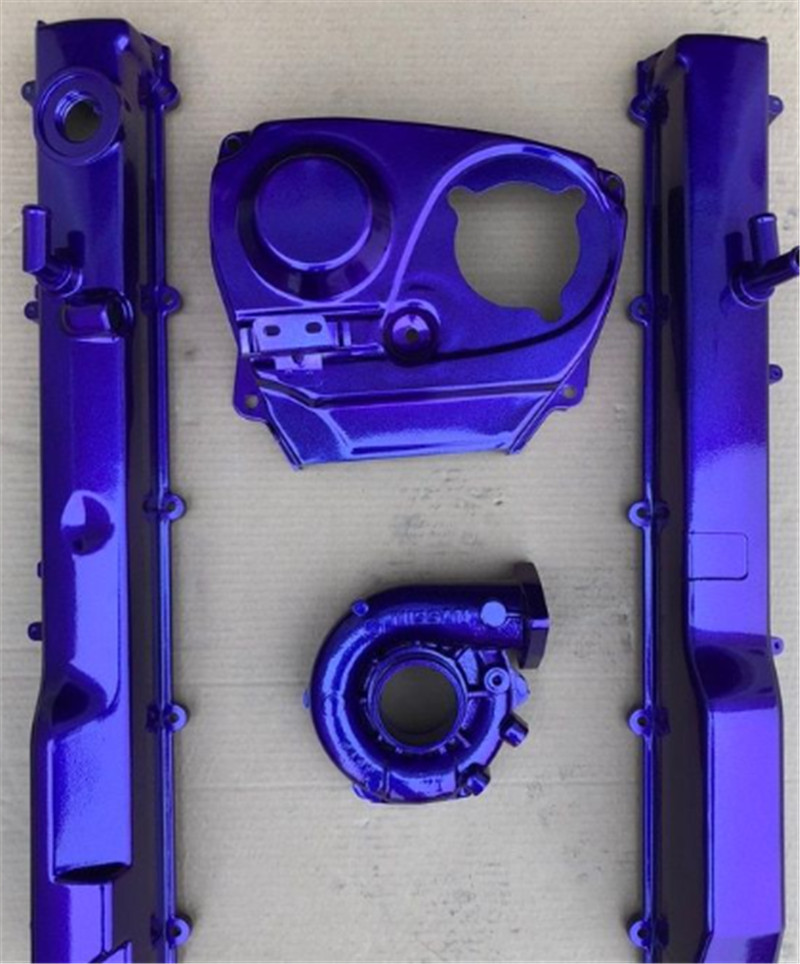

Kupfapfaidza pendi nekupfapfaidza hupfu

Kupfapfaidza pendi uye kupfapfaidza hupfu zvinhu zviviri zvinojairika pamusoro pekurapa mu Hardware zvikamu zvekupfapfaidza, uye ndiwo anonyanya kushandiswa epamusoro kurapwa kwezvikamu zvemaro uye diki batch customization.Ivo vanogona kuchengetedza pamusoro kubva mukuora, ngura, uye zvakare vanogona kuwana aesthetic maitiro.Zvese zviri zviviri zvekupfapfaidza hupfu uye pendi zvinogona kugadzirwa neakasiyana maumbirwo (mitsetse yakanaka, mitsetse yakaoma, mitsetse yematehwe, nezvimwewo), mavara akasiyana, uye akasiyana gloss mwero (matte, flat, high-gloss).

Sandblasting

Sandblasting ndeimwe yeanowanzo shandiswa kurapa pamusoro pezvigadzirwa zvehardware.Inogona kuvandudza hutsanana uye hutsinye, uye kuwedzera kunamatira uye kusimba pakati pechigadzirwa uye kupfeka.Naizvozvo, marapirwo mazhinji epamusoro anosarudza sandblasting sekutanga kurapwa kwavo.Zvakadai se: sandblasting + oxidation, sandblasting + electroplating, sandblasting + electrophoresis, sandblasting + dusting, sandblasting + pendi, sandblasting + passivation, nezvimwewo.

Teflon spraying

Iyo inonziwo Teflon kupfapfaidza, iyo yakasarudzika yakasarudzika pamusoro pekurapa.Iyo ine hunhu hwepamusoro hweanti viscosity, isina viscosity, yakanyanya kupisa tembiricha, yakaderera kukweshera, kuomarara kwakanyanya, kusanyorova, uye kukwirira kwemakemikari kuramba.Naizvozvo, inoshandiswa zvakanyanya muindasitiri yechikafu, tableware, kitchenware, indasitiri yemapepa, zvekurapa, zvigadzirwa zvemagetsi uye zvigadzirwa zvemotokari, makemikari michina, nezvimwewo, uye inogona kudzivirira zvinhu kubva mukuora kwemakemikari kuwedzera hupenyu hwebasa rezvigadzirwa.

Etching

Etching ndiyo nzira yekubvisa zvinhu uchishandisa kemikari kuita kana kuita kwemuviri.Kazhinji inoreva etching, inozivikanwawo se photochemical etching, zvinoreva kubvisa firimu rekudzivirira renzvimbo inozoiswa mushure mekuratidzwa kweplate yekugadzira nekusimudzira, uye kubata kemikari mhinduro panguva ye etching kuti iwane mhedzisiro yekuparara uye ngura, ichigadzira mhedzisiro concave-convex kana hollow molding.

IMD

MuMold Decoration (IMD) inzira inodhura yekushongedza zvikamu zvepurasitiki.Inosanganisira matanho mana: Kudhinda, Kugadzira, Kuchekerera uye Kuumba jekiseni.Uye Iyo tekinoroji inozivikanwa pasi rese yekushongedza kwepasi.Iyo yepamusoro yakaomeswa uye yakajeka firimu, iyo yepakati yekudhinda pateni layer, yekumashure jekiseni rekuumba layer, uye yepakati neingi inogona kuita kuti chigadzirwa chisarambe kukweshana., inodzivirira pamusoro kuti irege kukweshwa, uye inogona kuchengetedza ruvara rwakajeka uye kwete nyore kupera kwenguva yakareba.

Pad Printing

Pad printing, inonziwo tampografia kana tampo printing, indirect offset (gravure) printing process apo silicon pad inotora mufananidzo we2-D kubva palaser yakanyorwa (etched) printing plate (inonziwo cliché) yoendesa kune 3- D chinhu.Kutenda kudhinda kwepadhi, iko zvino zvave kuita kudhinda marudzi ese emhando dzakaoma dzakaumbwa senge curved (convex), hollow (concave), cylindrical, spherical, makomboni angles, maumbirwo, nezvimwewo izvo zvaive zvisipo nemaitiro echinyakare ekudhinda.

Kudhinda kwemvura yekufambisa

Kudhinda kudhinda kwemvura imhando yekudhinda inoshandisa mvura kumanikidza kuita hydrolyze bepa rekufambisa / firimu repurasitiki rine mavara emhando.Iyo tekinoroji maitiro anosanganisira kugadzirwa kwemvura yekufambisa bepa rekudhinda, kunyura bepa remaruva, kufambisa pateni, kuomesa, uye chigadzirwa chakapedzwa.

Conductive coating

Conductive coating imhando yepende inogona kushandiswa kupfapfaidza.Inogona kuitisa magetsi mushure mekuoma kugadzira firimu repende, kuitira kudzivirira kukanganiswa kwemagetsi.Parizvino, inoshandiswa munzvimbo dzakawanda dzemauto uye ehurumende maindasitiri akadai semagetsi, midziyo yemagetsi, ndege, indasitiri yemakemikari, kudhinda, nezvimwe.

Nguva yekutumira: Kubvumbi-11-2023